Fujii Iron Works Co., Ltd. has been selling full order-made products as a custom machine tool manufacturer for the automotive industry since our establishment in 1960.

We have earned the trust and respect of our customers with our sound awareness of their needs based on our long experience and know-how which enables us to develop products with high quality and high accuracy.

Design

Machine and jig design using two-dimensional and three-dimensional CAD

Manufacturering

Product manufacturing process

1Component machining

Major components requiring high accuracy such as spindles, NC slides, and work piece machining jigs are all manufactured in house.

2Surface finishing

All slide surfaces are finished by adjusting to 1/100mm precision with expert skill

3Assembling the lathe

Each of our custom tools are assembled by our assembly experts.

4Machining adjustment

Each machining work piece is optimally tuned in-house.

Products

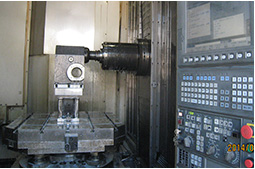

| MACHINE NAME | Vertical LATHE, TV 4NC |

|---|---|

| CHUCK SIZE | Howa 12 inch long stroke |

| TOOL POST | Gang tooling post |

| SLIDE STROKE | X: 160 mm Z: 400mm |

| SLIDE QUANTITY | FUJII Squire type: 2 Slide units |

| NC CONTROLLER | MELDAS FCA-C64 |

| SPINDLE SPEED | 50 ~ 800 RPM |

| SPINDLE MOTOR | MITSUBISHI SJ-V22 |

| ELECTRIC CAPACITY | 35 KVA |

| SIZE D・W・H | 2125 × 1950 × 2895 |

| WEIGHT | 4.5 TON |

Custom machining equipment

We design and manufacture all kinds of cutting machines optimized to the customer’s machining work pieces.

Disk rotors

Drums

Fly wheels

Bearing caps

Axle housing cases